DELIVERING EXCELLENCE FOR GAS PROCESSING NEEDS

- PSA NITROGEN GENERATOR

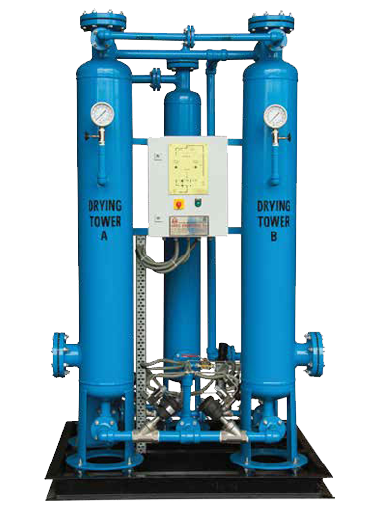

- DESICCANT AIR DRYER

- AMMONIA CRACKER

- CARBON MOLECULAR SIEVES

- ACTIVATED ALUMINA

- AND MORE..

GUARANTEED SOLUTIONS FOR

YOUR

GAS PROCESSING NEEDS

Futurex is one of the prominent organisation engaged in manufacturing, supplying and exporting of Industrial plant and equipment like industrial filters, industrial heat exchangers, ammonia cracking units , expo gas generators, gas exchangers , gas generators, compressed air / gas drying system, pressure vessels and others , supported by state- of- the- art manufacturing unit along with in – house quality and research and development department we have been able to offer the equipment that is at par with international standard. We are supported by a dedicated team whose ardent effort helps us in offering qualitative range of industrial process equipment and gas exchangers in stipulated time frame.

- PSA Nitrogen Gas Generator Plant

- PSA Oxygen Gas Generator Plant

- Air and gas dryer

- Hydrogen Gas Generator Plant

- Pressure vessel

- Air receivers

- Carbon molecular sieves (cms)

OUR MISSION

“Futurex mission is to provide cost effective machines, without compromising on the quality. futurex is striving hard to excel in the field of Oxygen Generators, Nitrogen Generators, Hydrogen Generators and other gas plants.”

OUR VISION

“Futurex vision is to educate client and make them empowered with latest knowledge and technology in the field of gas production”

NITROGEN GAS GENERATOR

Nitrogen Gas Generator produces nitrogen gas from atmospheric air based on PSA ( Pressure Swing Adsorption) technology. We provide variety of PSA Nitrogen gas generator, Nitrogen plant, in all kind of industries such as chemicals, Pharmaceuticals, Bulk Drugs, Food, Electronic Industry, Steel, Coal Mines, etc. PSA technique is simple and reliable process of separation of nitrogen gas from compressed air by adsorption of oxygen over a compact tower of carbon molecular sieves.

The “Treated” atmospheric compressed air enters and adsorption tower where it comes in contact of carbon molecular Sieves that binds the oxygen molecules and allows nitrogen to pass through void space. Pure nitrogen flows into the PSA Tower one and once the oxygen capturing capacity in a bed is diminished the feed switches to a new adsorption tower and the old bed is regenerated through rapid depressurization and is ready for the next cycle.

PSA NITROGEN SYSTEM COMPRISES OF FOUR

MAIN OPERATION

WORKING PRINCIPLE

Nitrogen generation plant based on PSA technology consists of 2 adsorber tower filled with Carbon Molecular Sieve (CMS). When pre-Filtered and compressed air is passed through the one adsorber, oxygen is adsorbed on the CMS and nitrogen gas comes out as the product gas. The waste gas(Oxygen, CO2, etc.) is discharged back into the atmosphere through silencer. During adsorption in one tower the second tower regenerates through depressurization to atmospheric pressure. This ensures continuous supply of Nitrogen gas to your process.

SALIENT FEATURES

- PSA Nitrogen Gas Generator Plant

- PSA Oxygen Gas Generator Plant

- Air and gas dryer

- Hydrogen Gas Generator Plant

- Pressure vessel

- Air receivers

- Carbon molecular sieves (cms)

APPLICATION

- PSA Nitrogen Gas Generator Plant

- PSA Oxygen Gas Generator Plant

- Air and gas dryer

- Hydrogen Gas Generator Plant

- Pressure vessel

- Air receivers

- Carbon molecular sieves (cms)

RELIABILITY

All our products are designed to be operated on a 24/7/365 basis. Simple operation, stable gas purity, minimum maintenance costs and a maximum system availability insure maximum customer satisfaction.

PURITIES

Nitrogen Gas Purity up to 99.999% can be achieved.

LONG LIFE, LOW MAINTENANCE

Unique design PSA Towers results no attrition loss of Carbon Molecular Sieves, No addition of CMS required, no-topping up required. Good quality valves ensure long life operation and minimum maintenance.

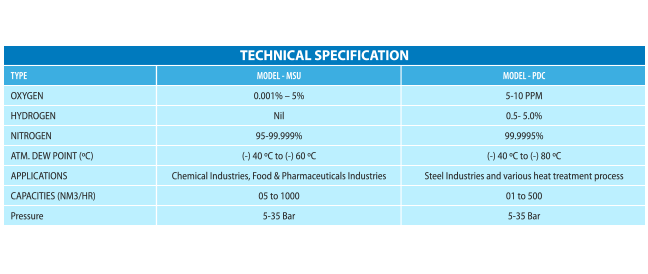

PDC MODEL

To achieve high Nitrogen gas purity up to 99.9995% PDC model will be required which is mainly used in Steel Industry for brightening purpose of pipes and tubes in Furnace.

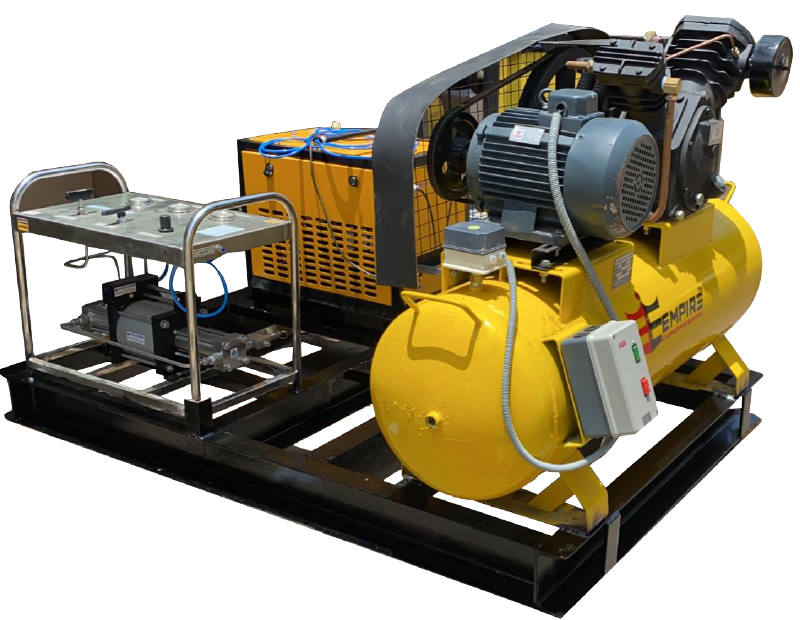

COMPRESSED AIR DRYER

In today’s Industrial zone this compressed air dryer is playing an important role in many application. Capitalizing on our manufacturing unit we design, manufacture and supply superior quality compressed air dryers and gas drying systems. Our designed Air Dryers is for high end Industrial applications to provide better protection against condensate damage. As per commercial point of view compressed air dryer are very cost effective and we also offer intelligent energy and Purge loss saving control for all drying processes.

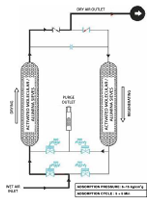

WORKING PRINCIPLE OF HEATLESS AIR DRYER

In Heatless Air Dryer two adsorber towers are filled with Activated Alumina/Molecular Sieves to adsorb the moisture present in the wet compressed air. Wet incoming compressed air or gas is passed through an adsorber tower where moisture is adsorbed to achieve better dew point. The dry air comes through the top of tower. After some time of operation alumina needs regeneration. Reactivation or regeneration of activated alumina is necessary to drive off the adsorbed moisture and to restore its absorptive capacity. This is accomplished via purging the adsorbent by dry air or gas at atmospheric pressure and temperature in reverse direction. The purge loss in around 10% of dry air. Changeover will take place through PLC/timer and continuous dry air will be received at outlet.

DRYER WITH ONLINE DEW POINT TRANSMITTER

Purgeloss of 10% is reduced up to 5% by integrating online dew point transmitter to the Sequential programmer. Drying Tower changeover takes place when dew point goes down the desired limit which results in huge saving of purge air.

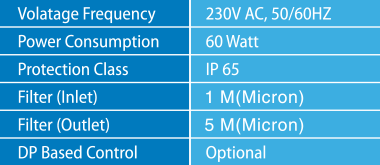

SALIENT FEATURE OF HEATLESS AIR DRYER

- Simple design filled with Activated Alumina as drying desiccant

- Capacity from 25 SCFM to 2500

- Dew point range(-) 40 to (-) 600C

- Pressure Range 5 to 15Kg/cm2g

- Power Consumption is only 60 watt to operate

- Solenoid valve

- Long Desiccant Life

- Low initial cost and operational cost

- Requires no maintenance

- Skid mounted modular design

APPLICATION

- Chemical

- Pharmaceutical

- Pneumatic Tools

- Painting Booth

- Pheumatic Control System

- Automobiles

PSA OXYGEN GAS PLANT

PSA Oxygen Plant plays a very important role in Medical, Glass, Fish and other Industry. Oxygen Gas can by generated through Pressure Swing Adsorption Technology, Oxygen Plant is designed to produce onsite Oxygen so that dependency of Oxygen cylinder can be free. This plant is automatic and required no such approval to install in the hospital.PSA OXYGEN PRINCIPLE

This process consist of two adsorber towers filled with Zeolite Molecular Sieve(ZMS) and Activated Alumina. Clean compressed air at 300C is passed through one adsorber tower and oxygen comes out as product gas. The exhaust gas (Nitrogen) is discharged back in to the atmosphere. Upon saturation of the ZMS tower the process switches oxygen generation to the other tower through change over valve allowing the saturated tower to undergo regeneration by depressurization and purging to atmospheric pressure. This process is continuous through PLC fitted in the control panel .Thus two adsorber tower automatically change over alternately in Oxygen Production and regeneration ensuring oxygen gas is continuously available to your process.

SALIENT FEATURES

- Capacity-5 to 200Nm3/hr

- Oxygen Purity-93% to 95% can be achieve easily

- Low Space Requirement

- Reliable, tested technology

- Fast Startup

- Fully Automatic

- Maintenance Free

- Reliable, tested technology

- Low Capital and running cost

- Fully customized equipments is available as

per customer requirement

per customer requirement

APPLICATION

- In Medical and Hospitals

- Glass Industry

- Chemical Oxidation

- Ozone Generation

- Steel Plate cutting

- Fish Industry

- Waste Water Treatment

PRESSURE VESSELS

Pressure Vessels are very commonly used in the industry. We design, manufacture and supply pressure vessels, air receivers and gas storage tanks as per the requirement of customer. We are having more than a decade of experience in fabrication of pressure vessels and air receivers.

We are manufacturing low pressure, high pressure and medium pressure vessels for variety of applications. Material of construction is generally kept as per customer requirement although mild steel and stainless steel is being used in majority. We are having strict quality policy to adhere with from beginning of design to final painting of vessels.

AMMONIA CRACKER

Cracked Ammonia finds wide application in steel industry for various heat treatment processes. We design, manufacture and supply customized ammonia cracker to meet customer’s demand as per their requirements. Heat treatment results are found very sound in the presence of mixture of hydrogen and inert nitrogen.

BASIC DESCRIPTION

Ammonia gas from cylinders passed over a bed of nickel catalyst at 8500 C temperature and cracking take place in two different gas i.e. 75% Hydrogen and 25% Nitrogen.

2NH3—N2+3H2 ( In Presence of Nickel catalyst at 8500 C)

Ammonia cracking is endothermic reaction and require heat from other source. The source is electrically heated/gas fired furnace (Rectangular Shape) and a retort made of heat resistance alloy is provided to hold the ammonia cracking catalyst.

Cracked ammonia from furnace is cooled to ambient temperature in a Shell and Tube type heat exchanger and having dew point around (-) 300 C. Further product gas is passed through a molecular sieves filled Gas Purifier to achieve a dew point up to (-) 800 C.

SALIENT FEATURES

- Centrifugally cast retort

- Furnace skin temperature is 200 C

- Dew point up to (-) 800C

- Heating Element is NI-Cr(80-20%)

- Long service cycle, Negligible maintenance

- High turn down ration

- Heavy duty operations for years and years

- Fully automatic no need of operator

APPLICATION

- Heat Treatment Furnace for bright annealing

- Brazing industry

- For Gas Purification System

- Stainless Steel Industry

- Power Sector

PSA HYDROGEN GAS PLANT

We design, manufacture, erection and commissioning of PSA Hydrogen Gas Plant, Hydrogen Gas Generator. Hydrogen gas is obtained from Cracked Ammonia by removal of nitrogen gas present in the mixture of H2 & N2. Our Hydrogen Gas Generator is combination of ammonia cracker and purification unit. Ammonia is cracked in ammonia cracking system and pass it through a purification system to remove nitrogen gas and achieved better dew point. Now this Pure Hydrogen gas can be stored in Hydrogen Storage Receiver. From storage tank hydrogen gas can be used to further application.

SALIENT FEATURES

- Hydrogen Gas Purity- 99%

- Dew Point- (-) 70°C

- Skid Mounted Unit

- High Performance

- Automatic Operation

- Steel and Metal Industry

- Energy & Power Industry

- Automobile Industry

- For Welding purpose

- Pharmaceutical Industry

OUR PRODUCT